UV Lithography

UV Lithography

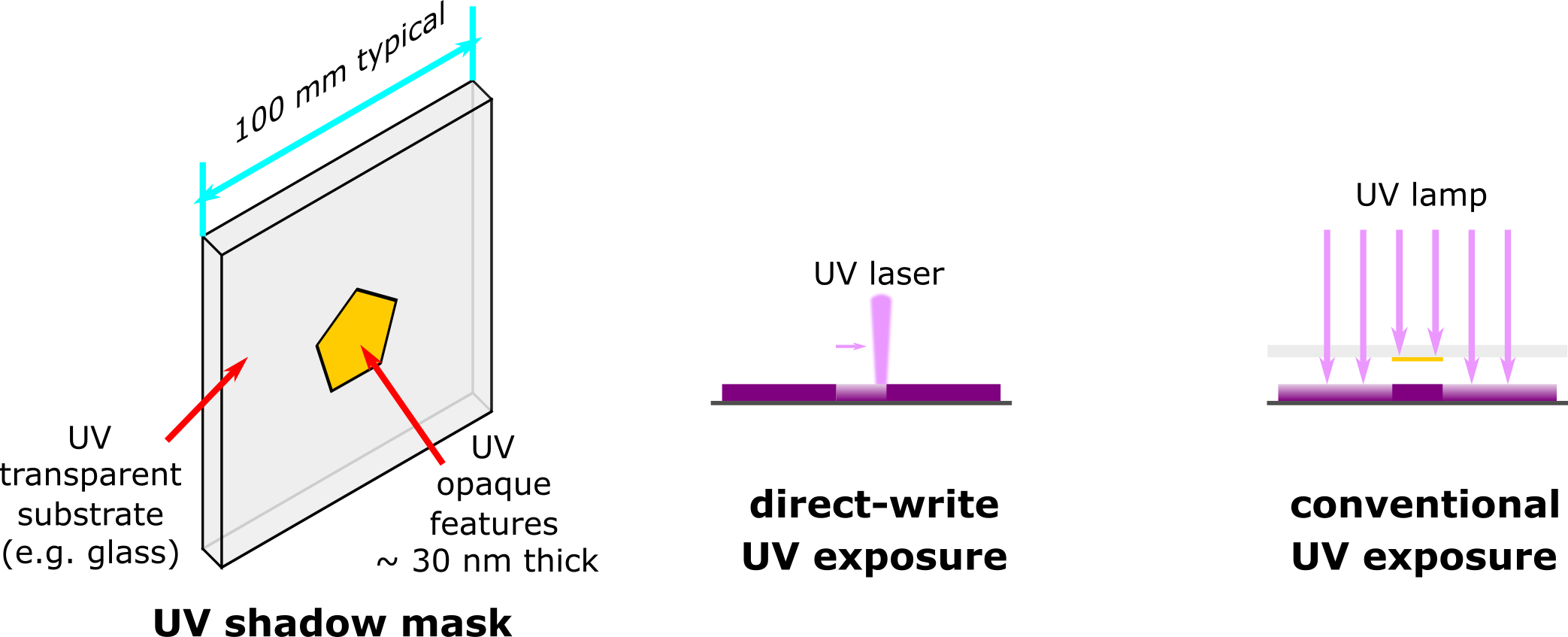

UV lithography can be accomplished via exposure through a shadow mask or with SyLMAND’s direct-write laser system. The Heidelberg Instruments DWL66+ direct write system uses a focused 355 nm UV laser which is rastered across a sample coated in UV-sensitive photoresist. Substrates up to 150 mm diameter can be exposed. Exposure induces chemical changes in the resist which result in differential dissolution rates in a solvent-based developer. Positive or negative tone resists are used in SyLMAND (see list below). After development, the desired pattern is revealed on the substrate after which further processing such as etching or metal deposition can be performed.

The direct-write laser system has two different write-heads (objectives) which balance resolution with write time. Theoretical resolutions are tabulated below assuming very thin resists (~ 500 nm) and optimal processing.

|

Write Head |

Theoretical Resolution |

Write Speed |

|

4 mm working distance |

0.8 um |

Slow |

|

10 mm working distance |

2 um |

Fast |

Exposures through shadow masks can be accomplished with the Oriel UV lighthouse. The lighthouse is equipped with a Hg vapour lamp.

Common Resists

Positive tone

- AZ1505 – 500 nm. Novolak phenolic resin-based resist with very good aqueous or concentrated acid compatibility. Prolonged exposure to concentrated oxidizing acids can degrade resist films. Sensitive to basic media and organic solvents.

Negative tone

- maN1407 – 700 nm. Lift-off resist used for templating sputtered metal structures. Controlling the development time provides undercuts in the resist sidewalls, allowing the resist to be easily removed after metal deposition

- SU-8 – 3 to 50 um. Epoxy resin with outstanding stability in almost every aqueous or organic medium. Biocompatible, optically transparent, and permanent. Also compatible with XRL.

- ADEX and SUEX – 10 um to 500 um, greater thickness on request. Formulation of SU-8 into solid sheet which is laminated onto substrate. Also compatible with XRL.

Critical Feature Size

Features made with the direct write system are theoretically limited by the size of the UV laser beamspot at focus. Likewise, exposure through a shadow mask is theoretically limited by the size of features in the mask. However, exposures are almost always practically limited by photoresist thickness and chemistry. Thicker resists have larger minimum feature size. This requires some experimentation to determine effective minimum feature size.

Aspect Ratio

Maximum achievable aspect ratio is generally lower than with XRL. For very thick resists sidewalls may have slight draft angles (few degrees) due to the converging UV beam.