About

SyLMAND, the Synchrotron Laboratory for Micro and Nano Devices at the Canadian Light Source, is accepting General User proposals for polymer-based microfabrication. SyLMAND consists of a dedicated X-ray lithography (XRL) beamline and pre- and post processing laboratories in a cleanroom environment. High aspect ratio patterning at the XRL beamline is typically based on PMMA photo resist and is applied for applications including micro optics and fluidics. Subsequent electroplating of the patterned polymer can be used to produce metal micro parts as used in various Micro Electro Mechanical Systems (MEMS). Masks required in the XRL process can be fabricated based on user CAD layouts utilizing SyLMAND’s in-house mask making technology. Alternatively, a wide variety of user-owned XRL masks can be applied at SyLMAND. SyLMAND masks are fabricated using mask-less UV lithography, which can also serve as a stand-alone technique to pattern UV sensitive photoresists such as SU-8.

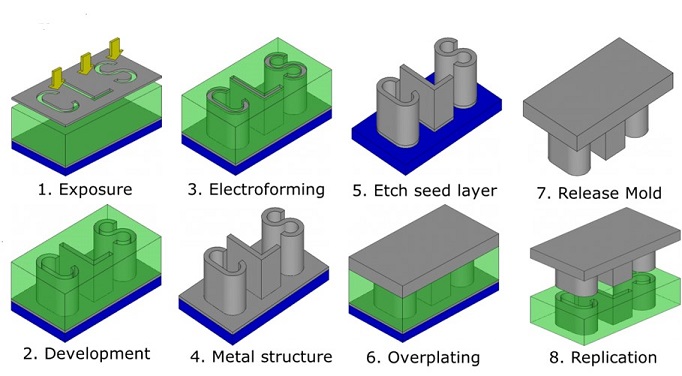

The process flow diagram below illustrates main processing steps at SyLMAND: X-Ray Lithography (steps 1 – Exposure and 2 – Development, together delivering primary polymer microstructures) and subsequent process steps form the so called LIGA process (LIGA is a German acronym for Lithography, Electroplating, and Replication): After electroplating (steps 3 – 5), an inverse metal structure is obtained. Replication steps (6 – 8) are not currently available at SyLMAND.

Typical LIGA steps. (lithographie galvanoformung abformung/ lithography electroplating forming). Steps 6,7 and 8 are not available at SyLMAND at this time.

Applications

SyLMAND serves a wide variety of academic and industrial users in engineering and physical sciences. Current areas of application include next-generation antennas, biomedical devices, microfluidics, and x-ray optics.

SyLMAND X-ray Lithography Beamline

SyLMAND Cleanroom